ディスカバリー ファーマPQ

A comprehensive print quality inspection and data verification system for pharmaceutical label, leaflet & packaging applications

For most industries, packaging plays a critical role. From protecting and securing the product, increasing its appeal, to communicating important marketing and product information. However, printing errors on packaging can result in massive recalls and obsolete inventory costs for the Printer, whilst exposing them to risks due to regulatory non-compliance and lower product safety. When it comes to printing errors on pharmaceutical packaging, whether on the packaging itself, on an attached label or on an associated printed leaflet with the medication, this can have more serious, sometimes life-threatening consequences.

In many countries, specific legislation governs what information needs to be printed on pharmaceutical packaging to combat the growing threat of counterfeit medicine. In Europe, for example, the Falsified Medicines Directive (FMD) 2011/62/EU requires all medication to have a serialized number which enables the package to be tracked and traced throughout the supply chain. Also, pharmaceutical packaging printers need to check the final print against the original approved artwork and notify the authorities of any changes.

It is estimated that 50% of pharmaceutical recalls are due to errors in product labeling or packaging artwork. Furthermore, printing errors such as missing, incorrect or unreadable medication names, strength, lot/serial numbers or expiry dates can confuse or mislead people into taking the wrong or inappropriate medicine. Error in dosage instructions where e.g. “2.5mg” appears as “25mg” or “2-3 tablets” is printed as “23 tablets”, can potentially cause serious harm or even fatalities. These printing errors could easily occur due to a number of prepress, production or operational issues. Blocked or misfiring inkjet heads, toner marks, dust, equipment/software glitches or human error (e.g. keying errors) could and do happen at any time.

Manual print quality inspection or using strobed video web viewing systems (which monitor only small portions of the web), is grossly inadequate for catching small or random print defects, leading to higher reprint costs, inventory obsolescence and operational pressures – which impact profits, lower customer satisfaction and your ability to secure future business. In turn, if these errors go out undetected, the repercussions could be even worse, exposing you and your clients to negative publicity, damaging penalties, lawsuits and regulatory action.

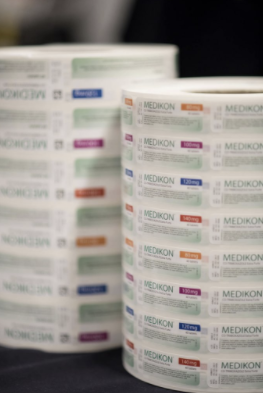

Introducing… DISCOVERY PharmaPQ a comprehensive print quality inspection and data verification system for pharmaceutical applications, capable of monitoring 100% of the web using high-performance line scan imaging and automated defect detection technology for web print, labels, and packaging applications.

DISCOVERY PharmaPQ has been recognized as a Red Hot Technology (formerly called a MUST SEE EM award) at this year’s PRINT18 show in Chicago, September 30thto October 2nd, 2018.

- 採用される業界別

- ソリューション別

- 印刷品質

- 1Dコード、2DコードのISOグレード検証

- RFID 読取/書込み統合品質検査

- LIS: 印刷工程を統合化した画像検証システム

- 可変情報検証

- 外部データマッチング : データ印字の全数管理に必須の外部データとのインラインマッチング

- 印刷工程生産管理

- 画像処理製品別

- Maxscan: コンタクトイメージセンサー(CIS) –コンパクト、高解像、高速処理

- PQ Express:印刷品質検査ヘッドをワンパッケージ化。 コンパクト、高速処理

- ロールインスペクター : ラベルロール出荷前の最終検査

- Pharma PQ : 製薬業界向け印刷品質検査、トレーサビリティ検証システム

- 可変印刷データ検査用 超コンパクトシステム

- 目的別検査ツール: 全体を、Discovery Suiteという名のソフトウエア群

- 検査後の履歴報告、トレーサビリティ: Discoveryソフトウエア

- カスタムデザインシステム管理

下記の社名をクリックして直接当社への問い合わせも可能です。

株式会社リベロ

〒151-0053 東京都渋谷区代々木2-23-1-773 電話:03-3370-6373

支店:〒144-0052 東京都大田区蒲田1-18-10 電話:03-5714-7330